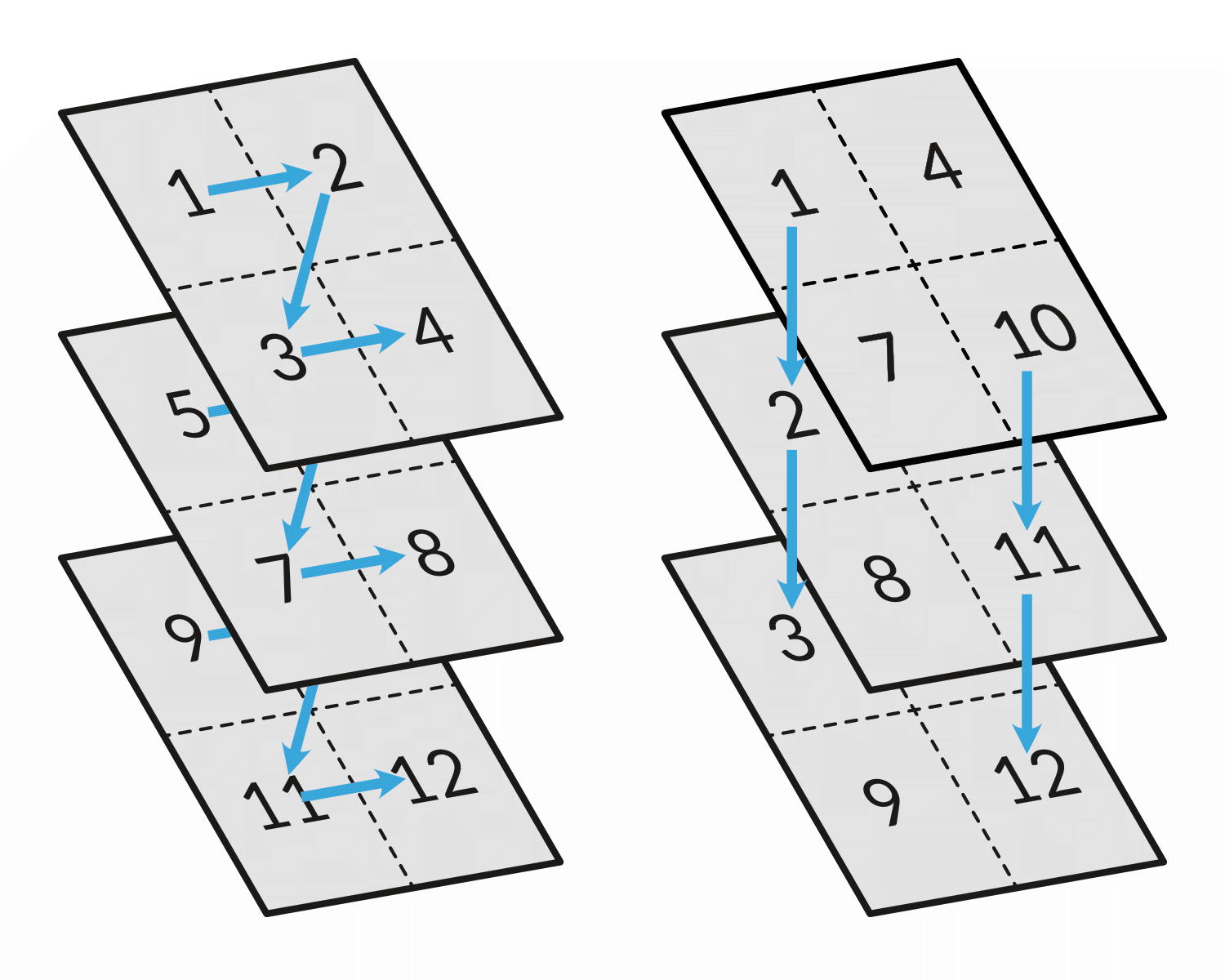

With our most recent visit to the “Great Minnesota Get Together”, we were reminded of a successful project where we delivered a brilliant solution to the Competitions staff at the Minnesota State Fair. They’d been printing out exhibitor tags on card stock with a layout optimized for printing. FileMaker was already doing a great job of finding the relevant records and going to a layout with the fields they needed that would be printed three to a page. However, when FileMaker sorts records for printing, you are given only 2 choices: Across first or Down first.

This works great for printing address labels as you end up with each label in order, in either rows or columns, depending on your selection. If instead you are printing cards that get cut apart, you end up with individual stacks that are not in order. This results in many piles that are difficult to keep in order, especially if you are printing hundreds of records.

Our client summed up the challenge: “The problem is that it’s so many pages. Then they get cut into thirds which leaves them even more out of order because the three piles that it makes aren’t in any real order after being cut. I can’t really solve the problem of cutting in thirds because that would seem like some impossible programming.”

To help solve the problem of losing tags after they were cut, they asked us to alter the scripting to allow printing in smaller batches. We did add the ability for the staff to enter a range of IDs to print the tags in smaller batches, but while this solved one problem, it inadvertently created more work, not less!

At LuminFire, we rarely find challenges are impossible, they just require brilliant thinking! Drawing on our team’s past experience in the printing industry, one of our team members knew the way to achieve a solution. He would often have requests to print custom items that were sequentially numbered, or ordered in some specific way. To make the most efficient use of paper, printers would print several cards up on each sheet. In industry lingo, this is referred to as “N-up printing”, where N represents the number of individual items on the sheet. If there were four to a page, we would call that a “4-up” layout.

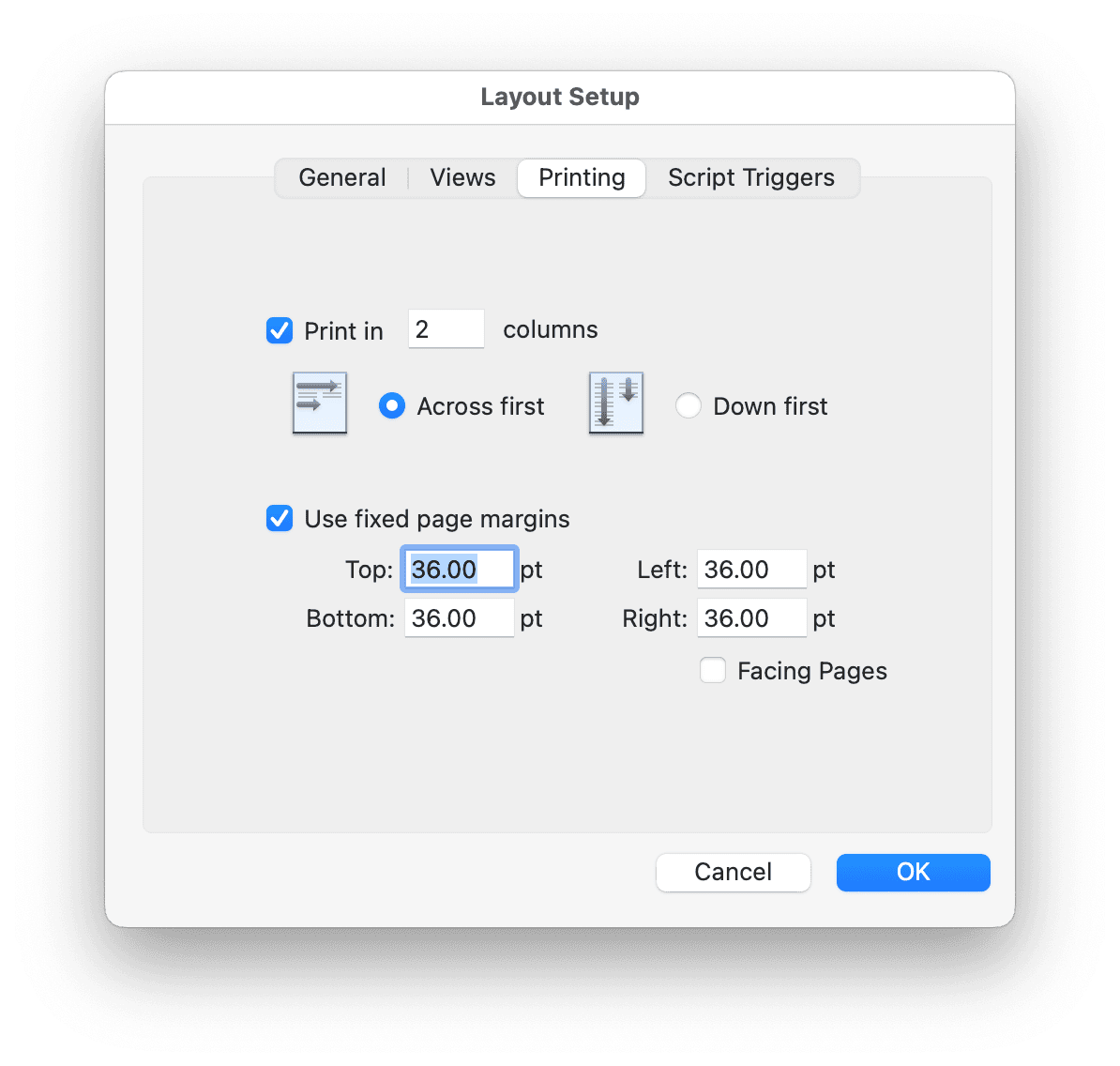

FileMaker may not be the first tool you think of for commercial printing, but it has a flexible layout mode for just this type of thing. To solve the problem, we created a calculated field that would take a variable representing the N-up number, and turn that into a custom sort number. The calculation is purposefully unstored, so that no data needs to be altered for this to work. That way, modification timestamps don’t change when you run this.

In the script, you tell it the number of records that will print on a page, then go to the corresponding layout that matches. Then you first sort your records in the normal, desired order. Then you re-sort the records based on the unstored calculation. The result is records that will print in an order so that once you cut the items apart, each stack will be in sequential order (of course, this assumes you have a guillotine-style paper cutter that can handle the job).

The left diagram shows FileMaker’s normal “across first” sorting, and the right shows cut stack sorting.

This solution was a big win that improved efficiency for the MN State Fair staff during a season that is very hectic and fast paced. They were very pleased: “Wow! That is super cool! I never cease to be amazed at what you can make FileMaker do with data.”

Want to try it out yourself?

This sample file has 24 numbered records. You can add more if you like, but that is enough to see what is happening under the hood. On the main layout, there are buttons that bring up a preview window, sorted for printing 3-up, 4-up, or 6-up. Notice when you move through the pages of the preview that the record numbers drill down from page to page, rather than moving around each page, one at a time. Note: The calculation will work with any number up that your layout demands, and any number of records.

Download the FREE “LuminFire Cut Stack Sorting Demo.fmp12” file below.